When's the last time you thought about where your household goods, clothes, skincare, and food came from? Who makes them? What impact are they having on your body, family, and environment? It's easy to become so far removed from the products we use everyday.

This is Do One Better, a weekly newsletter highlighting the true cost behind common goods. We try to make this the most informative and actionable email you get on Thursday mornings. If you enjoy this content, please show some 💕 and share with friends!

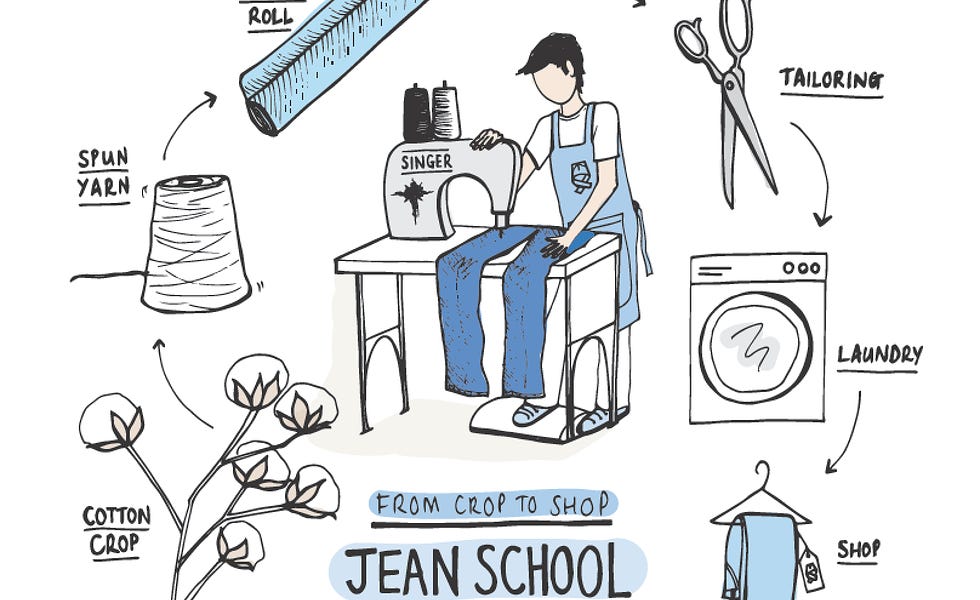

For our first piece, let’s take a look at a constant staple in everyday fashion — denim blue jeans.

Known for their versatility, durability and timeless style, denim jeans are something you know everyone has a pair of in their closet. At any given time, half the world’s population is rocking jeans, making it the most popular casual item.

At a Glance

Denim jean manufacturing has long moved out of the U.S. to across the globe — Mexico, Bangladesh, Italy, Pakistan, and China — and the mass production of denim jeans has skyrocketed.

Over 5 billion pairs of denim jeans are produced every year. The world’s jean capital, Xintang, China, produces over 300 million pairs of jeans everyday. That's almost one new pair of jeans for each person in the U.S., everyday.

Jean prices vary from as low as $20 (H&M, Zara, we're looking at you) to $400. But how much do jeans truly cost?

From an environmental standpoint, communities in these regions face dire circumstances: 70% of Asia's rivers and lakes are contaminated by the 2.5 billion gallons of wastewater produced by the textile industry. People that depend on these rivers for drinking and bathing suffer from higher incidences of cancers and skin conditions. To make matters worse, the textile factories in China emit 3 billion tons of soot each year, contributing to 30% of China's total yearly CO2 emissions.

Environmental Effects

Breaking in your jeans takes time and patience, but it turns out that manufacturers do most of the heavy lifting for us. The jeans that you buy come pre-distressed or pre-washed. Here's how:

Washing: Stonewashing gives a faded, worn-out look to the fabric in large washing machines.

Dyeing: Bleach jeans to decolorize and create different colors.

Finishing: Creates whisker effects on denim, lightening certain areas.

Sanding: Fades areas of denim using manual tools to wear down the garments.

All of these steps use high amounts of water, chemicals, and labor.

Traditionally, it takes about 1½lb. of cotton to make one pair of jeans. This means the entire process takes around 7000 liters, or 1800 gallons, of water, 1.5 kW of electricity and 5 oz. of chemicals. That could provide 10 years of water for a single person.

Factories, often unregulated, dump most of this dark toxic blue denim dye into nearby rivers, polluting the water. Piles of blue fluff collect in the river, increasing the water’s pH level and adding metals into the soil.

Jeans manufacturing also produces an enormous amount of carbon dioxide, with Levi Strauss estimating 20.04 kg of CO2 emitted per pair of jeans, or the same as driving about 42 miles in your car. This includes fabric production, packaging, and transportation required to get your jeans to the store.

Human Labor

A common sentiment of outsourcing manufacturing is that people are given jobs. BUT, most of our clothes are made in places where worker's rights are nonexistent. The garment industry employs every 6th person on the planet.

These workers are:

Paid poorly, as low as ⅕ th of their living wage while being forced to work 14-16 hour days, 7 days a week in poor lighting at temperatures as high as 100 degrees.

Breathing in toxic chemicals and denim dust that comes from sanding, at least 400 pairs of jeans a day. The impact? Skin rashes, infertility, and lung infections.

80% women, who bear much of the gender-based discrimination and abuse reported in these industries in reports of sexual harassment at work.

The collapse of the 8 story Rana Plaza in Dhaka, Bangladesh killed more than 1,100 people in 2013, representative of the horrible working conditions in the textile industry.

The Future of Denim

Even with all of these environmental and labor concerns, it is hard to convince people to purchase and wear raw denim jeans. Instead, manufacturers look to create pre-distressed jeans with more environmentally focused methods, using less water, bleaching, and sandblasting.

Here are a few groups you can read more about to see how their identifying companies with sustainable and ethical practices in denim and organic cotton:

Labels: Global Organic Textile Standard, B Corp, Cradle to Cradle Products Innovation Institute, Better Cotton Initiative

Research: Aitex, SA 8000, Bluesign, Jeanologia, WRAP

Events: Ellen MacArthur Foundation

Steps manufacturers have done to improve their jean production include:

Creating water-free indigo dyes

Reducing water during the dyeing process.

Removing the stones out of stonewashing with enzymes and new washers.

On the labor front, major retailers like Levi’s, Wrangler, Lee are funding a two year program "that establishes an independent investigative group where factory workers can raise concerns". And as we call attention to apparel factories, workers in cotton fields and transporting jeans are often still neglected.

It’s still unclear whether these are marketing tactics or a true commitment to labor standards, but hopefully this is a good place to start.

Current Alternatives

We tried digging up some alternatives to fast fashion jeans to help you do one better...but we realized how expensive they are 😥. Producing environmentally friendly, sustainable, and with lower supply/demand is expensive.

If you're interested in seeing what other alternatives are out there, here's a list of more sustainable and conscious jean brands (minimum price is ~$100) from Good on You.

Jeans Today

We'll shamelessly admit that it's been a while since we've worn jeans, because comfort >>> during the pandemic and working from home. Well, we weren't the only ones who've chosen Lululemon over Levi's.

Because of the pandemic:

Casual wear is winning. People are opting in for comfort wear, and we are right there with you. Jeans sales have been sluggish for five years, but they were hit hard in the pandemic. Levi’s even cancelled slim fits for baggy ones because of this.

Sales of “super premium” jeans — at least $200 — slid more than 40 percent, as Americans traded down to lower-priced denim and athletic wear.

Retailers are cancelling over 8 billion dollars worth of denim orders and refusing to accept clothing that had been finished but would no longer be able to sell. This led to 1 million+ workers losing their jobs in Bangladesh, with many facing destitution, and the rise of sexual abuse of women garment workers.

Consumers want companies to do the right thing. When the BLM movement called for political change, 66% Gen Z shoppers said a company’s transparency and response would permanently affect their decision on whether to buy from them or not.

What You Can Do

Whew! That was a lot to get through. Now onto how you can do one better:

Buy less! Do you really need that new pair of boyfriend jeans that are one shade darker?

Buy second hand or thrifted jeans. Denim lasts for a very long time, and even those made 40 years ago still hold their value today.

If you want to buy new, opt for jeans with natural dyes and made from organic cotton. Look out for ones that have GOTS or approved by groups listed above.

Make your jeans last longer by either washing less (the smell test tells all) or changing the way you wash them.

Recycle your unwanted jeans and other clothing. Check out how to do so in your city.

Learn more about the impacts of denim by reading the links throughout this article.

Questions or comments on this piece? Suggestions on what we should cover next? Send us a note.